Filter press plates are an essential component of a filter press system, which is used to separate solids from liquids in a variety of industries.

Here are some key things you need to know about filter press plates:

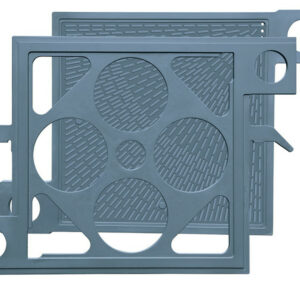

Material: Filter press plates can be made from a variety of materials, including polypropylene, stainless steel, cast iron, and ceramic. The choice of material depends on the specific application requirements, such as the type of material being filtered, the required filtration rate, and the maximum operating pressure.

Plate types: Filter press plates come in various types, including recessed chamber plates, membrane plates, and plate and frame plates. Each type has its own unique design and filtration characteristics.

Plate sizes: Filter press plates are available in a range of sizes, typically ranging from 250mm to 2000mm in diameter. The size of the plates depends on the size of the filter press system and the amount of material being filtered.

Filtration area: The filtration area of the filter press plates is an important factor in determining the filtration rate and efficiency. The filtration area is calculated by multiplying the plate size by the number of plates in the filter press system.

Plate configuration: Filter press plates can be configured in various ways, including single-sided or double-sided filtration, and with different numbers of chambers or membranes. The configuration of the plates depends on the specific application requirements and filtration goals.

Maintenance: Proper maintenance of filter press plates is essential to ensure optimal performance and longevity. filter press plate This includes regular cleaning, inspection for damage or wear, and replacement of worn or damaged components.

Customization: Filter press plates can be customized to meet specific application requirements, such as the addition of coatings or surface treatments for improved durability or chemical resistance.

Overall, filter press plates are a critical component of a filter press system, and their design and characteristics play a key role in determining filtration performance and efficiency. Consult with a filter press plate supplier or manufacturer to determine the best plate design and material for your specific application needs.

Weight filter press plate And How to Think About Them

The weight of filter press plates can vary depending on the material and size of the plates.

Here are some considerations to keep in mind when thinking about the weight of filter press plates:

Material: The weight of filter press plates can vary depending on the material they are made from. For example, polypropylene plates are typically lighter than stainless steel or cast iron plates.

Size: The weight of filter press plates increases with size, so larger plates will generally be heavier than smaller plates. The weight of the plates should be taken into account when designing the filter press system and selecting the appropriate components.

Handling: The weight of filter press plates is an important consideration when it comes to handling and installation. Heavier plates may require additional equipment or personnel to move and install, which can increase costs and time.

Structural support: The weight of filter press plates can also impact the structural support required for the filter press system. Heavier plates may require stronger support structures to ensure stable and safe operation.

Shipping and transportation: The weight of filter press plates can impact shipping and transportation costs, as heavier plates may require special handling or transportation arrangements.

When thinking about the weight of filter press plates, it is important to consider the specific application requirements and the trade-offs between weight, durability, and performance. Consult with a filter press plate supplier or manufacturer to determine the best plate material and size for your specific application, taking into account factors such as filtration rate, operating pressure, and handling requirements.