1, the use of laser cutting machine: what is the scope of application of laser cutting machine?

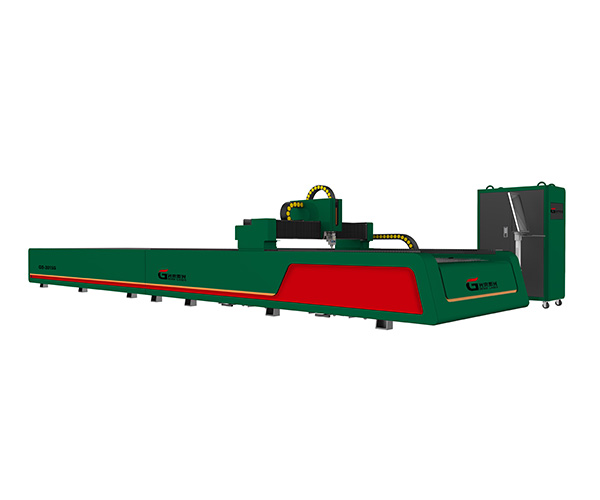

Metal fiber laser cutting machine is used in sheet metal processing, aviation, aerospace, electronics, electrical appliances, subway accessories, automotive, food machinery, textile machinery, engineering machinery, precision parts, ships, metallurgical equipment, elevators, household appliances, crafts and gifts, tool processing, decoration, advertising, metal outside processing, kitchenware processing and other manufacturing and processing industries. Stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized plate, galvanized plate, pickled plate, copper, titanium and other metal plates and tubes cutting.

2, the use of laser cutting machine: what is the principle of laser cutting? What is the use?

The principle of laser cutting is to use a high power density laser beam to scan the surface of the material, in a very short period of time the material is heated to thousands to tens of thousands of degrees Celsius to melt or vaporize the material, and then use high-pressure gas to melt or vaporize the material. The vaporized material is blown away from the slit for the purpose of cutting the material.

The investment in laser cutting equipment is relatively large. Most of them are currently used to cut thin steel plates and some non-metallic materials. The cutting speed is fast and the accuracy is high. However, laser cutting will produce arc marks and thermal effects at the cutting slit; in addition, laser cutting is not ideal for some materials, such as non-ferrous metals and alloys like aluminum and copper, especially for cutting thicker metal sheets, the cutting surface is not ideal or even impossible to cut. The current research on high-power laser generator is to solve the cutting of thick steel plates, but the cost of equipment investment, maintenance and operation consumption is also considerable. Water cutting small investment, low operating costs, cutting a wide range of materials, high efficiency, easy to operate and maintain. Laser cutting apprentice to learn how long.

3, the use of laser cutting machine: what is the role of laser cutting machine?

Laser cutting machine has many functions and is currently widely used in various fields, such as: furniture, home, textile and clothing, medical equipment, aerospace manufacturing, automotive ships, sheet metal processing, hardware products, electronic appliances, advertising industry, etc.. It is a kind of manufacturing industrial laser processing. A big company like Da Clan Yuming Laser has developed industry-specific laser cutting machines according to the characteristics of different industries. His CO2 laser cutting machine should be one of the most complete in the industry. It can cut various materials, such as metal, non-metal, fabric, leather, foam, wood, plastic and other materials.

4, the use of laser cutting machine: what is the use of laser cutting machine

Laser cutting machine is widely used for many industries and a variety of materials. The performance and use of laser cutting machine.

Sheet metal processing, advertising sign word production, high and low voltage electrical cabinet production, mechanical parts, kitchenware, automotive, machinery, metal crafts, saw blades, electrical parts, glasses industry, spring pieces, circuit boards, electrical kettles, medical microelectronics, hardware, knife and measuring instruments and other industries.